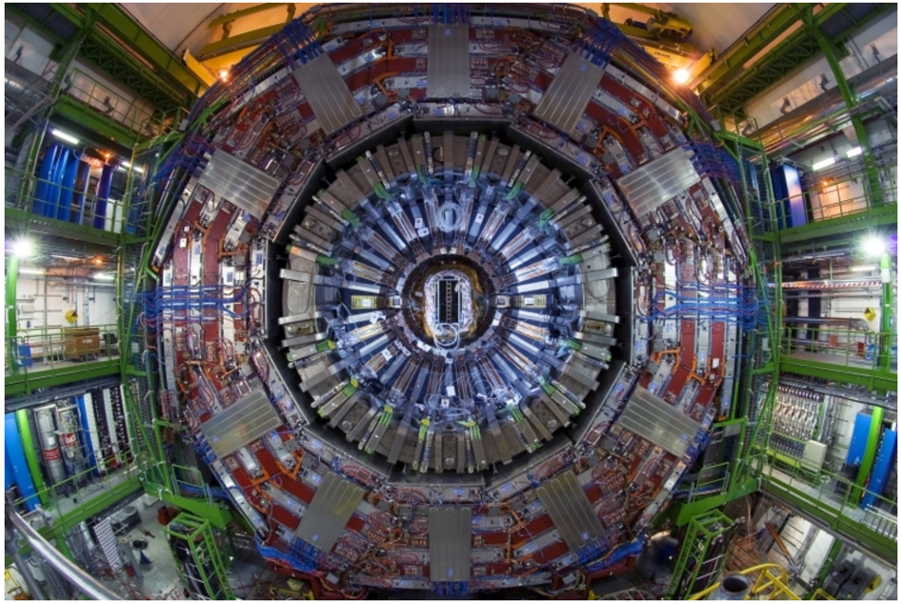

The CMS electromagnetic calorimeter (ECAL) measures the energy of electrons and photons produced in the LHC collisions with extreme precision. It includes, as main active element, 75848 scintillating crystals made of lead tungstate, a material that is heavier than iron but transparent as glass. The crystals are arranged in a barrel section and two endcaps. The barrel part is made of 36 super-modules, 18 on each side of CMS, each containing 1700 crystals, and is installed in CMS inside the barrel hadron calorimeter (HCAL).

During the third Long Shutdown (LS3), currently foreseen to start in 2025, all ECAL barrel super-modules must be extracted from CMS to replace their electronics with ones better suited for operations with high intensity beams. This activity will take about one year. Each ECAL super-module weighs about 3 tonnes, and must be handled with extreme care to avoid damaging the crystals. A dedicated machine called the “enfourneur” is used to extract and insert back the super-modules inside CMS.

The enfourneur was designed by the ECAL group of the CEA/Saclay laboratory and was used to install the super-modules inside CMS in 2007. It provides robust, smooth and careful handling of the precious ECAL crystal super-modules. It looks like a big rotating cage with one slice missing. The empty slice is oriented upwards and allows the insertion of one super-module using a crane; once the super-module is firmly attached to the machine, the cage rotates to reach the desired insertion slot, then it slides forward approaching the hadron calorimeter; once the correct alignment is checked, the super-module is gently pushed into its slot in CMS. In 2007 the enfourneur was installed on a concrete block tower and operated at a height of about 10 metres from the cavern floor. The installation and alignment of the enfourneur with respect to CMS are delicate and long operations to ensure safe handling of the super-modules. The third Long Shutdown will last about two and a half years and many concurrent upgrade activities must be carried out. In order to speed up the extraction and insertion operation of the ECAL super-modules it is foreseen to use two enfourneurs, operating on opposite sides of CMS in parallel. This allows to gain about three months’ time. The INFN Rome group is responsible for the second enfourneur. The two machines must be as similar as possible, to simplify their use by the operators.

Using the feedback of the team that installed the super-modules inside CMS in 2007, the first enfourneur has been improved, increasing the space for the operators: all walkways and stairs have been redesigned and space in narrow passageways has been increased. Fixation points for the harnesses have been reviewed. Extended rails to connect to the hadron calorimeter at larger distance have been designed to allow extraction/insertion from a retracted position in case installed cables prevent from approaching the hadron calorimeter closely. Recently several insertion tests with dummy loads have been carried out, to test the new rails and walkways in the CMS surface assembly hall in Cessy, France. Many tests at different angles have been successfully completed.

The enfourneur drawings have been cross-checked and updated using a 3D scan of the existing structure and a measurement campaign has been carried out by engineers from CERN and INFN Rome. Lowering and installation plans have been made in order to speed up the installation operations and a new alignment system based on laser light has been designed.

In order to cross-check some details of the original installation in 2007, the ECAL team has revived the photos taken by the camera that was installed in the CMS cavern at the time of construction. This camera, the so-called “CMS eye”, was taking one photo every few minutes. A movie has been made using these photos, with the insertion of the ECAL super-modules in CMS.

After three years of collaboration between CMS integration, CMS Technical Coordination, CERN survey team, ECAL Technical Coordination, CERN, Saclay and INFN Rome groups, ECAL is ready to launch the production of the second enfourneur which should be delivered in 2023, well in advance of the start of LS3.

- Log in to post comments