The TBPS Rings are in production, offering an innovative design to incline sensors toward the LHC beam and maximise coverage. They are the first support structures in production for the new Tracker!

As part of the CMS Hi-Lumi Tracker, construction of the Tracker Barrel with Pixel-Strip modules (TBPS) is underway. The innovative Tilted sections of the TBPS have gone through many design iterations and have been in production since 2024. The design prioritises efficient use of material, therefore lowering costs while maximising coverage.

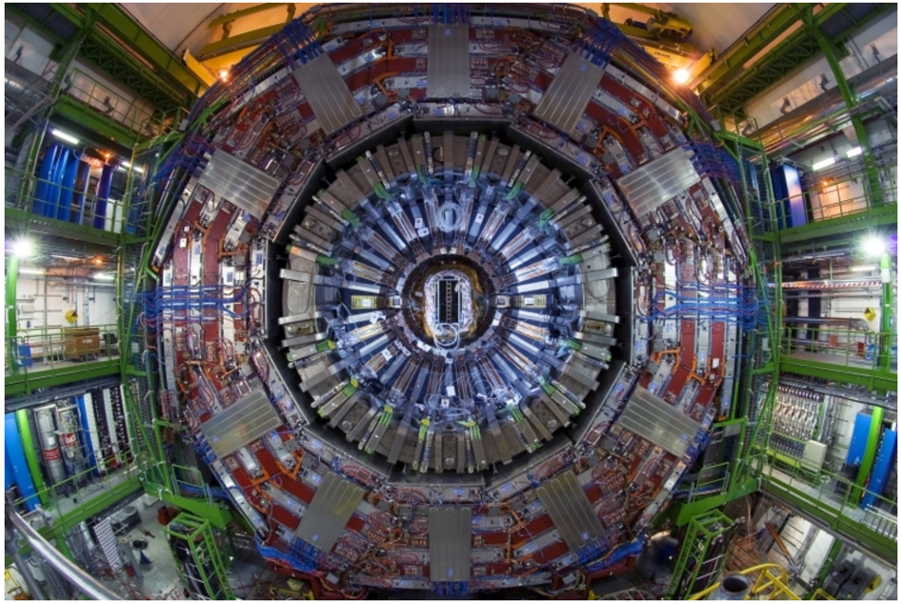

The Tracker for Hi-Lumi CMS consists of the ‘Inner Tracker’ and the ‘Outer Tracker’ and will reconstruct the paths of charged particles as they travel through the detector.

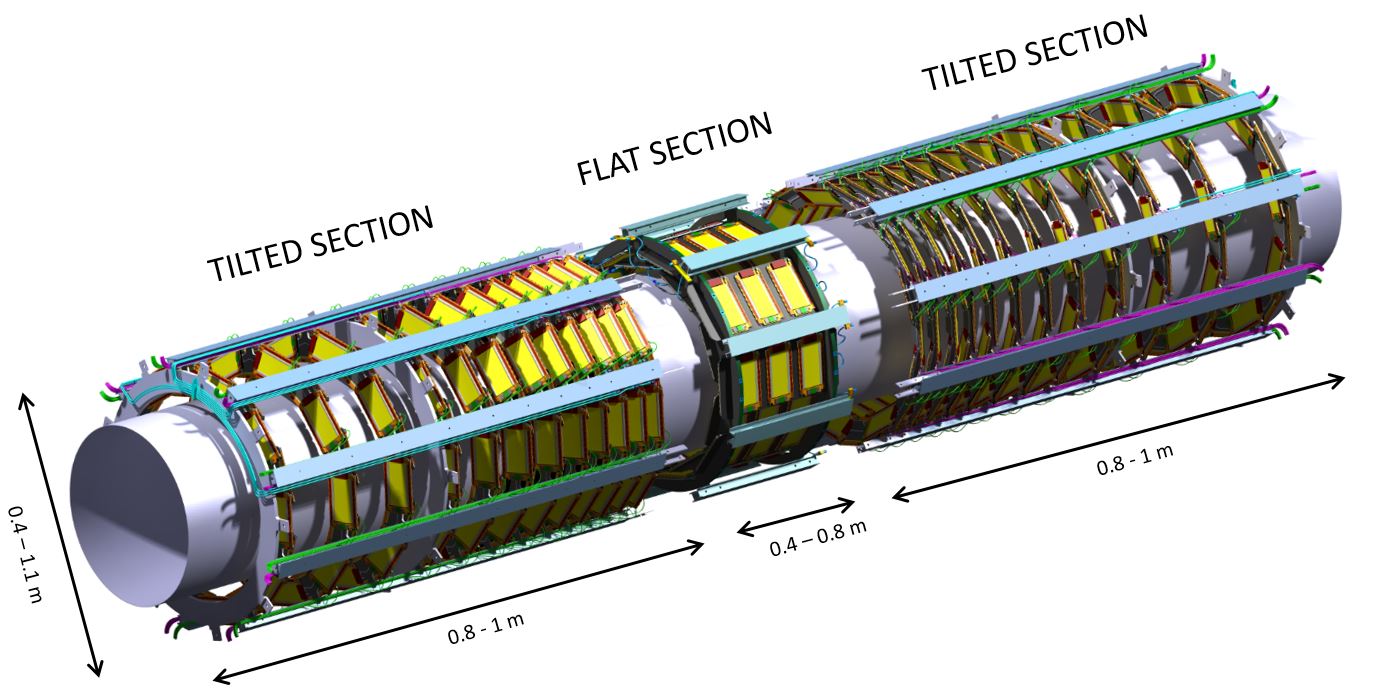

The TBPS forms the first three layers of the new Outer Tracker, using Pixel-Strip, or “PS” modules, consisting of one silicon macro-pixel sensor and one silicon strip sensor. Each TBPS layer has a “Flat” central section, where the PS modules are aligned parallel to the beam line, and two “Tilted” sections, where the sensors are slightly inclined towards the LHC beam interaction point.

Above: 3D model showing one layer of the TBPS

“Rings” are the key structural components of the Tilted TBPS. The Rings hold and position the PS modules at varying tilt angles to maximise the spatial coverage of each module. Compared to the classic “barrel” and “endcap” arrangement, such a tilted geometry minimises the number of modules needed, and therefore the total material and cost of the detector. The tricky part of this – and one key reason why such detector geometries with small increases in tilt angle are so innovative and were never constructed before – is the complicated mechanical arrangement.

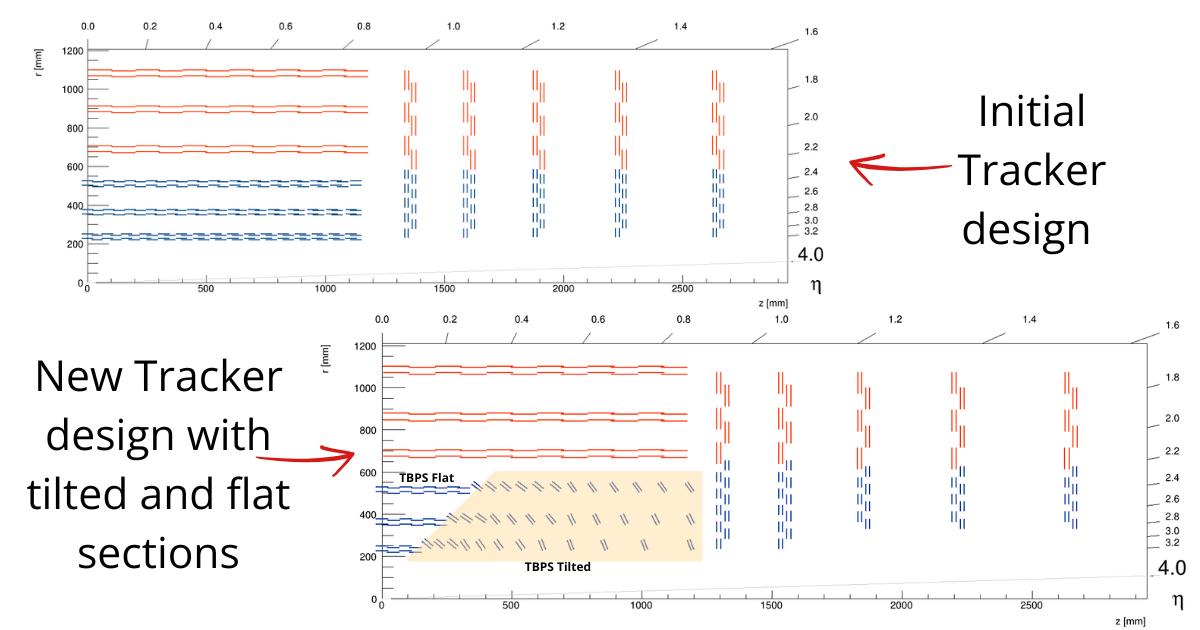

Above: Layout of a quarter of the Outer Tracker.

Top: Initial layout: many more PS modules (in blue) would be needed, considerably increasing the amount of material crossed by the particles.

Bottom: Current Layout with TBPS Tilted highlighted: this specific geometry minimises the number of modules and grants the best efficiency in track collection.

The mechanical design and construction of the TBPS Rings are done by CERN, while the PS module integration onto the TBPS Ring mechanics is done in INFN Pisa. The integration of the Rings in two complete TBPS “Tilted” sections will be done in the Tracker Integration Facility (TIF) at CERN.

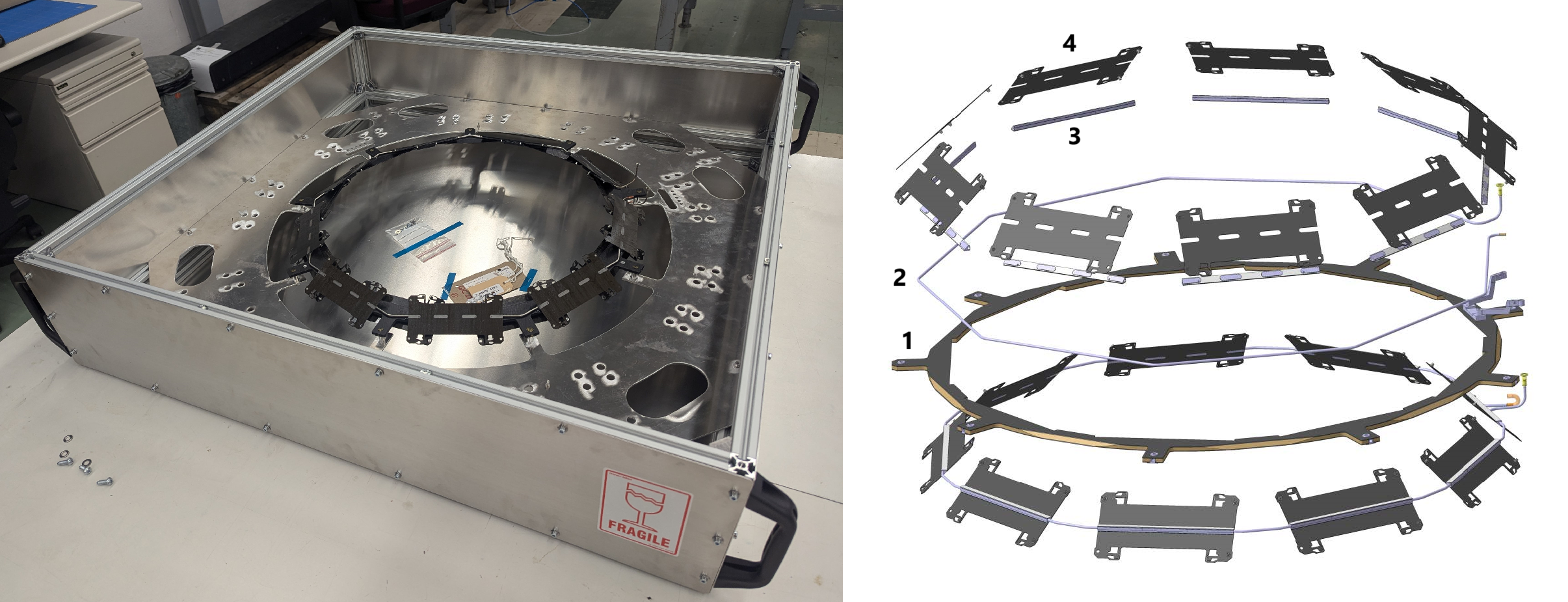

Above Left: Ring carrier box to transport Rings to INFN Pisa and back to CERN.

Above Right: Exploded view of the 4 main components of a Ring assembly.

The TBPS Rings come in three sizes (ranging from 60 cm to 115 cm in diameter) to match the three layers. Each Ring consists of four main components:

- 5 mm thick sandwich structure with 4 mm polyetherimide (Airex) foam core and 0.5 mm thick carbon-fibre-reinforced polymer (CFRP) skins.

- Thin-walled stainless steel cooling pipes to circulate CO2 at -35°C, used to maintain the silicon sensors parts at optimal temperature.

- Cooling adapters made of aluminium/carbon-fibre composite.

- 0.5 mm thick carbon-fibre cooling plates, one for each PS module.

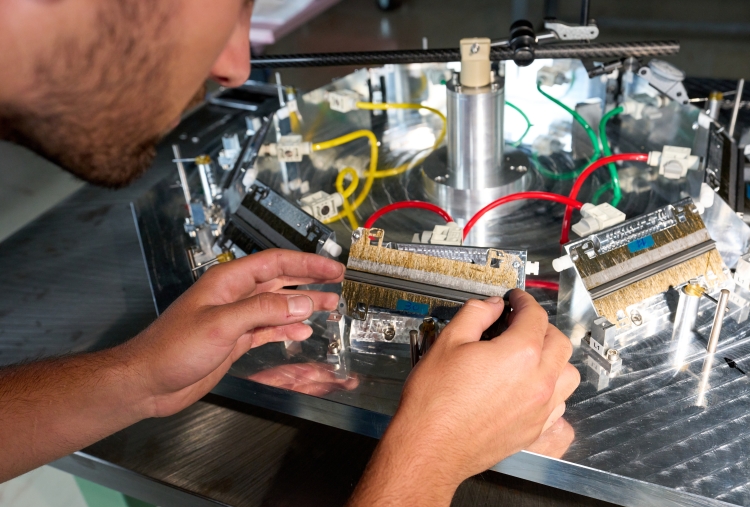

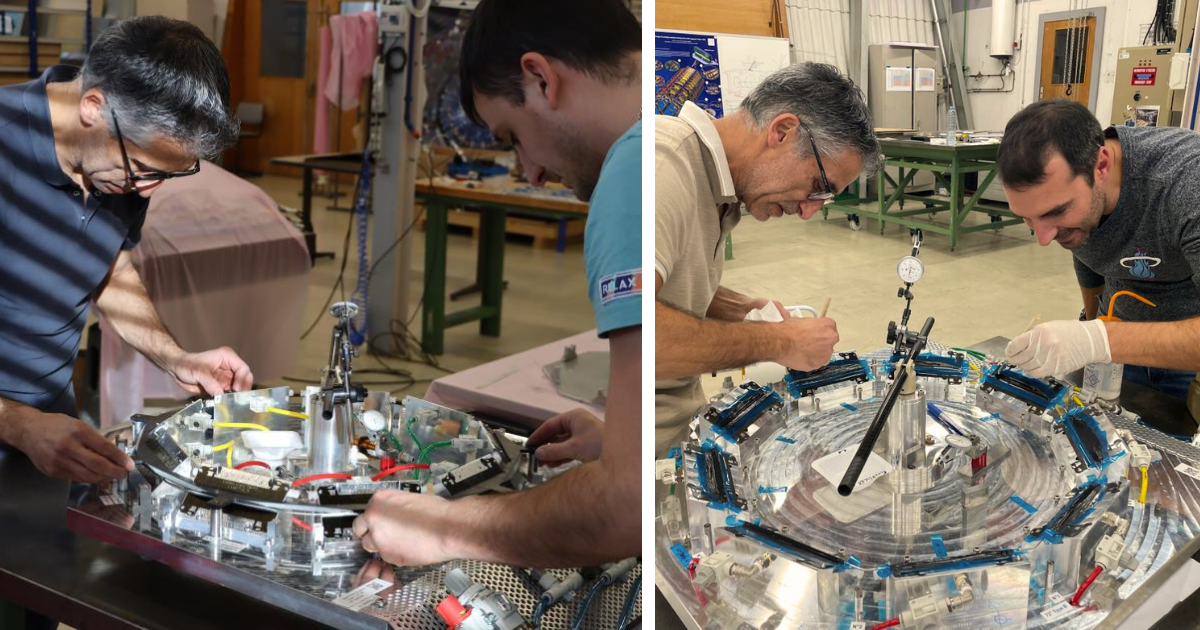

The Ring design employs lightweight, high-conductivity composite materials to minimize interference with particles, to ensure structural stability over 10 years of operation, and to remove heat generated from the detector modules to the CO2 coolant. All components are assembled in a temperature and humidity-controlled environment using radiation-hard epoxy glue and precise aluminium jigs, ensuring geometrical accuracy within 100 microns for the module positioning.

The design of these TBPS Rings began over a decade ago. Early concepts, including shell structures and beams, were evaluated before the current design was chosen as it allowed better management of the tight overlaps between the neighbouring modules. Moreover, the Ring design offered welcome structural stability, and useful sub-structure modularity that helps the production.

The first full-scale Ring prototype was completed in 2019 and went through extensive validation tests. The pre-production of the final Rings started in 2024, and, from autumn 2024, has been proceeding at full speed, with approximately one Ring produced per week. To date, almost 50% of the required 72 Rings have been completed. Production is foreseen to reach completion around the spring of 2026.

Above: Some of the first TBPS Rings in production.

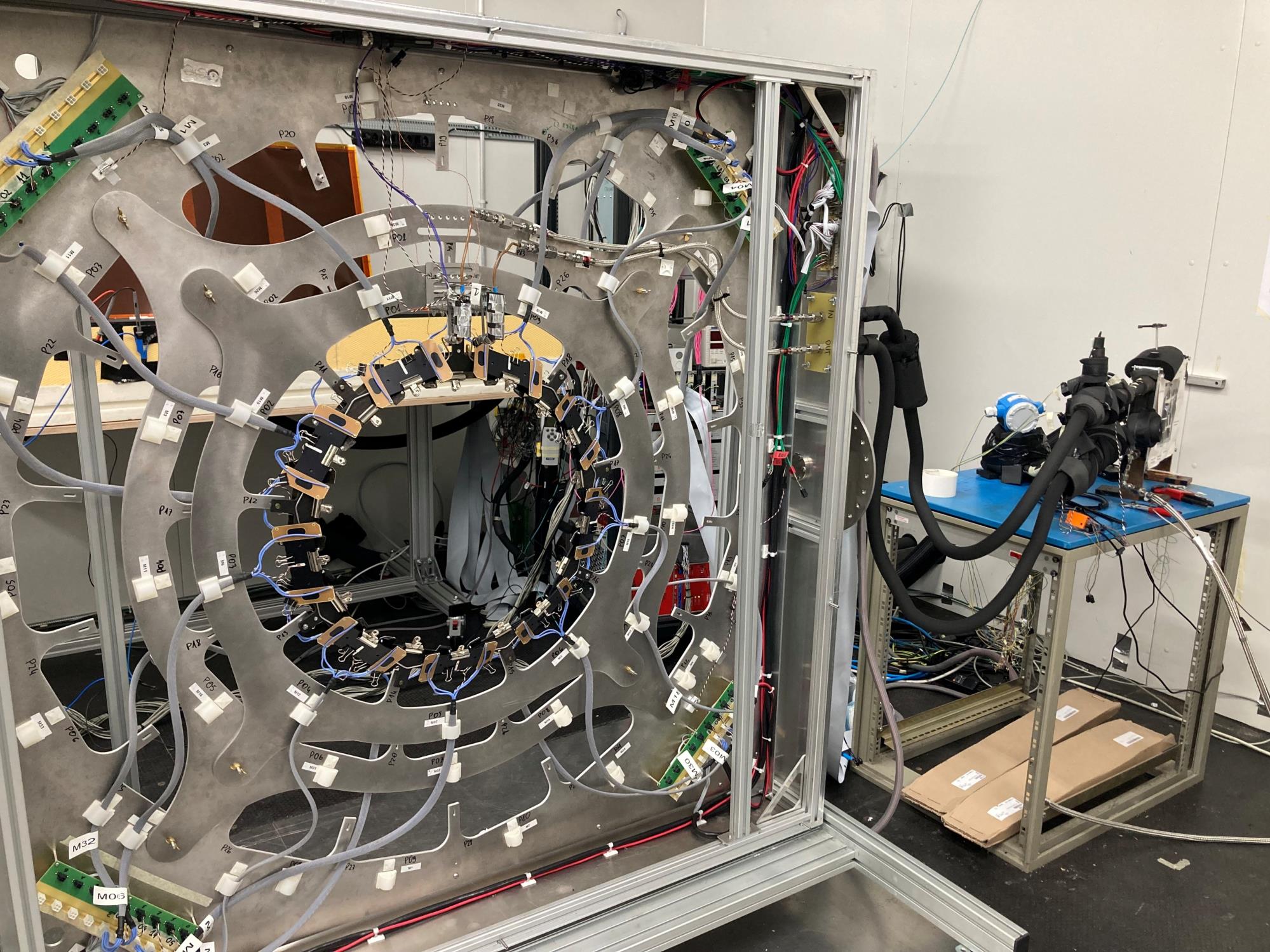

Careful production and quality control are crucial throughout the process. All assembly jigs and components undergo stringent dimensional checks before use. During assembly, every step is verified, including monitoring of the glue curing. Once assembled, each Ring undergoes a comprehensive battery of quality control checks, including:

- Dimensional inspection using a Coordinate Measuring Machine (CMM).

- Stiffness and mass measurement.

- Leak and pressure testing of the cooling pipes.

- Thermal performance testing, where CO2 is circulated through the pipes, and dummy loads simulate real module heat dissipation.

Above: Thermal test setup to validate the CO2 cooling of the Ring.

Once a Ring has passed all tests it is ready to be sent to INFN Pisa for the module installation. The loaded and tested Rings will then return to CERN, where they are assembled into the six TBPS Tilted sections, two per layer. At the end of this integration process, scheduled throughout 2025 to 2027, the tilted sections will be joined with the flat sections to form the final TBPS detector, ready for the Hi-Lumi CMS Tracker.

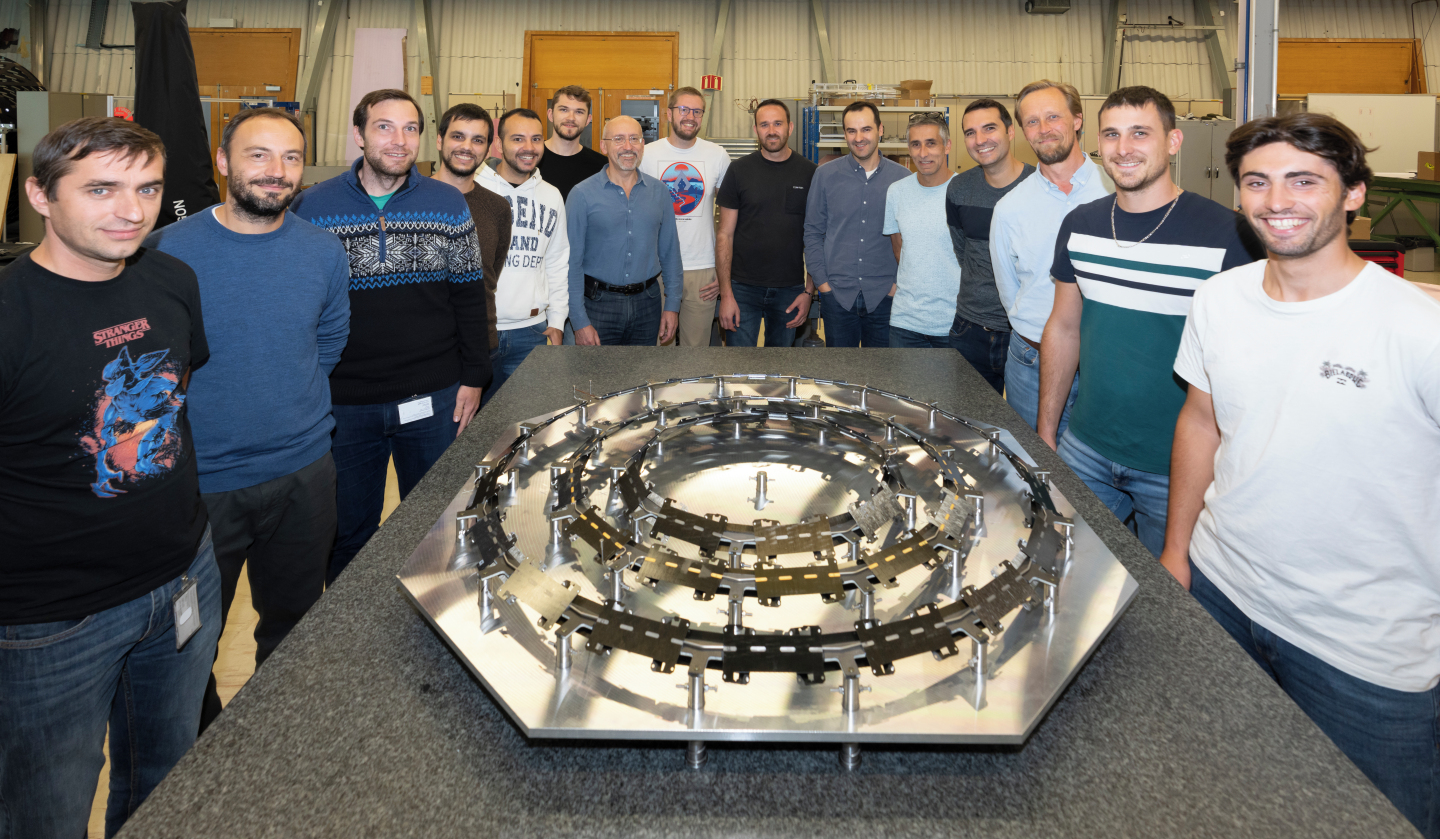

Above: Members of the CMS TBPS Team (Image: M. Cavazza | CERN)

Further links:

Initial production photographs

Tour of CMS laboratories including the TBPS labs on CERN site