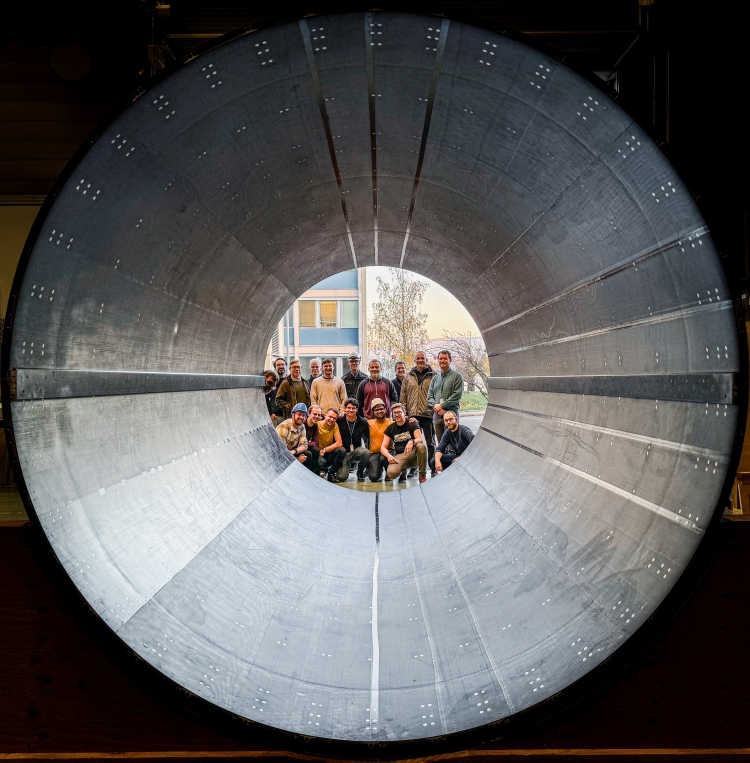

Above: Part of the BTST team during the unboxing of the tube. (Image: Noor Abduljalil J Abdulla)

In a massive step toward CMS’ High-Luminosity era detector, a key component of the build has arrived at the CERN laboratories.

CMS has received a very big box! The BTL-Tracker Support Tube (BTST) is a carbon fibre cylindrical structure designed to sustain the future CMS silicon Tracker and the Barrel Timing Layer (BTL), key components of the future CMS detector.

In preparation for CERN’s High-Luminosity LHC, all the particle detectors on the LHC are undergoing vast changes. This is to make the most of the increased luminosity and to continue recording as many interesting collision events as possible, even in conditions much harsher than the current ones.

The BTST is 5.3 metres long, almost 2.5 in diameter, and perfectly cylindrical, with only one and a half millimetres of distortion allowed. It is an essential component, built to be able to support a combined mass of about 5 tons between the Tracker and the BTL – all while weighing only about 600 kg itself!

In order to create something both so strong and so lightweight, the design is made of 2 carbon fibre sheets enveloping a light, honeycomb structure, for a combined thickness of just 3 cm.

This specialised design was a joint project of the Tracker and BTL engineers and physicists, under the leadership of the Purdue CMS group and the Composites Manufacturing & Simulation Center (CMSC) at Purdue University. The tube itself was manufactured in industry by a specialized company in California, Rock West Composites Inc. in 2023.

However, after production in San Diego, it had to make its way in perfect condition all the way to Switzerland. It took a long road trip to Purdue for quality checks and extensive testing to make sure the minute tolerance was not exceeded, which took several months of precise measurements. Then it traveled onwards to Chicago O’Hare airport.

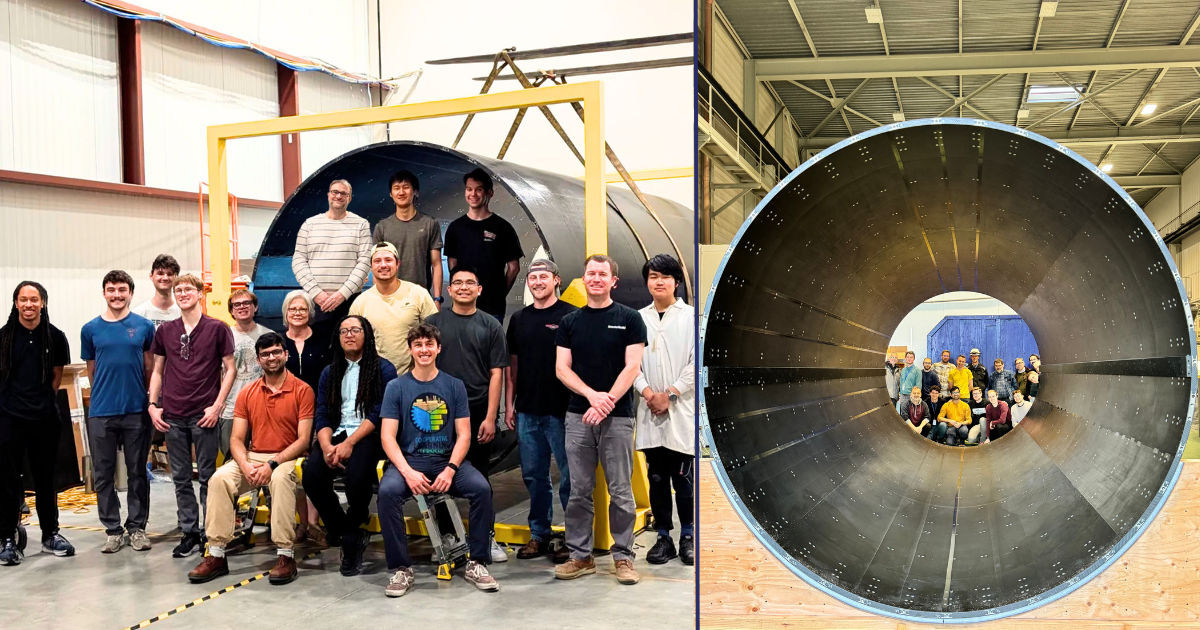

Above: The BTST being tested at Purdue University

During the transport between Purdue and the airport, the box was damaged in a road accident and had to be returned to Purdue University. After 3 months of extensive inspections at Purdue (visual, laser, ultrasonic tests) it was confirmed that the BTST was in perfect condition. A final test, loading a weight of 2800 kg, validated the strength of the BTST structure. After a formal review of the results, the BTST was declared ready for onward transport to CERN.

The large box holding the BTST, although huge, does fit into an airplane - just. In order for it to fit, the edges of the container box had to be cut off! However, cargo planes able to transport such huge boxes cannot just land anywhere, and the closest possible airport was in Luxemburg, where it was loaded onto a truck and driven to Geneva. It made it through import formalities and acceptance checks before finally arriving at CERN.

Above: On the left is the original box that was just too big to fit on the plane, and on the right is the modified box to get it onto the plane.

Now the tube is being checked before the next steps: its outer surface will be covered with heating foils to thermally insulate the Tracker and BTL. This is because they need to be kept at -30°C, achieved through CO2 based cooling, whereas the tube will be surrounded by other components at around 10°C. That is a difference of approximated 40°C across those tiny 3 cm!

Then, the BTL will be installed on the inner surface of the tube: 72 trays full of BTL modules will be inserted. The BTL modules were designed to be very thin, using the best precision-timing technology available: a crystal scintillator coupled to silicon photomultipliers. This will allow to achieve a time resolution of about 35 ps.

The full Tracker will be installed inside the Tube: the Outer Tracker (6 layers and 10 wheels, 5 for each side, of double-sensor modules) and the Inner Tracker (4 layers and 24 disks, 12 for each side), for a total weight of about 2500 kg. The Inner Tracker will need to be installed in another tube, being built at Purdue, Inner Tracker Support Tube (ITST), again in carbon fibre composite material, and installed once the Outer Tracker is completed.

All the teams are very excited about the arrival of the BTST and are eager to dive into the next steps towards that High Luminosity era: the Tracker and BTL assembly can officially start!

Above: From Purdue to CERN: some of the teams on both sides of the Atlantic. (Image: Right: Purdue Team, Left: Noor Abduljalil J Abdulla)

Watch a timelapse of the unboxing of the tube at CERN

Further Reading:

Timelapse of the BTST arriving at CERN and being unboxed here

Fermilab feature on the BTST arrival

New precision timing detector for the CMS HL-LHC upgrade - the MTD

Crystals for precision timing arrive in Rome - BTL crystals

Rock West Composite wins a CMS Industry Award 2022

Award winning prototype’s successful review leads to $1.5M manufacturing funding for CMS detector

BTST structure received at Purdue

CERN Courier news (2004) of the current CMS Tracker tube | with photos here