Detectors consist of layers of material that exploit the different properties of particles to catch and measure the energy and momentum of each one. CMS needed:

- a high performance system to detect and measure muons,

- a high resolution method to detect and measure electrons and photons (an electromagnetic calorimeter),

- a high quality central tracking system to give accurate momentum measurements, and

- a “hermetic” hadron calorimeter, designed to entirely surround the collision and prevent particles from escaping.

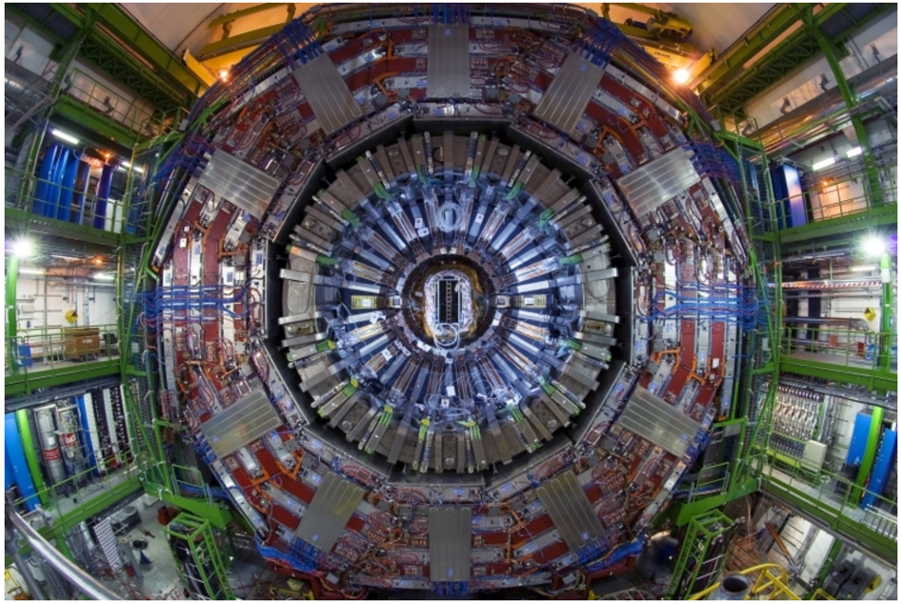

Sectional view of the CMS detector. The LHC beams travel in opposite directions along the central axis of the CMS cylinder colliding in the middle of the CMS detector. Click on the image to enlarge.

With these priorities in mind, the first essential item was a very strong magnet. The higher a charged particle’s momentum, the less its path is curved in the magnetic field, so when we know its path we can measure its momentum. A strong magnet was therefore needed to allow us to accurately measure even the very high momentum particles, such as muons. A large magnet also allowed for a number of layers of muon detectors within the magnetic field, so momentum could be measured both inside the coil (by the tracking devices) and outside of the coil (by the muon chambers).

The magnet is the “Solenoid” in Compact Muon Solenoid (CMS). The solenoid is a coil of superconducting wire that creates a magnetic field when electricity flows through it; in CMS the solenoid has an overall length of 13m and a diameter of 7m, and a magnetic field about 100,000 times stronger than that of the Earth. It is the largest magnet of its type ever constructed and allows the tracker and calorimeter detectors to be placed inside the coil, resulting in a detector that is, overall, “compact”, compared to detectors of similar weight.

The design of the whole detector was also inspired by lessons learnt from previous CERN experiments at LEP (the Large Electron Positron Collider). Engineers found that building sections above ground, rather than constructing them in the cavern with all its access and safety issues, saved valuable time. Another important conclusion was that sub-detectors should be made more easily accessible to allow for easier and faster maintenance.

Thus CMS was designed in fifteen separate sections or “slices” that were built on the surface and lowered down ready-made into the cavern. Being able to work in parallel on excavating the cavern and building the detector saved valuable time. This slicing, along with the careful design of cabling and piping, also ensures that the sections can be fully opened and closed with minimum disruption, and each piece remains accessible within the cavern.

These considerations, along with the unique conditions of the LHC, affected the design of each layer of the detector. To read about the design of each sub-detector, click on the links in the left-hand menu.

- Printer-friendly version

- Log in to post comments