One otherwise unremarkable day, the meeting of the CMS group at the University of Minnesota Physics Department took an unexpected, yet not entirely uncommon, detour to the pages of the web. This particular detour had brought us to the delightful collection of photographs detailing the University of Maryland group’s creation of a Lego model of our beloved CMS detector. It was after feasting our eyes on the fruits of their labours that a question arose in one of our heads: “Why isn’t there a CMS cake?”

For a time, the idea remained an academic curiosity at best. However, as we idly raised questions –– such as “What would ECAL be?” –– we found that a surprising number of those had well-defined answers. The decision itself to create our brainchild was more of a second-order phase transition. We simply realised one day that every major subsystem could be constructed using commonly available food products, and from then on it was merely a matter of getting three physicists to act coherently towards a common goal, which is no small feat.

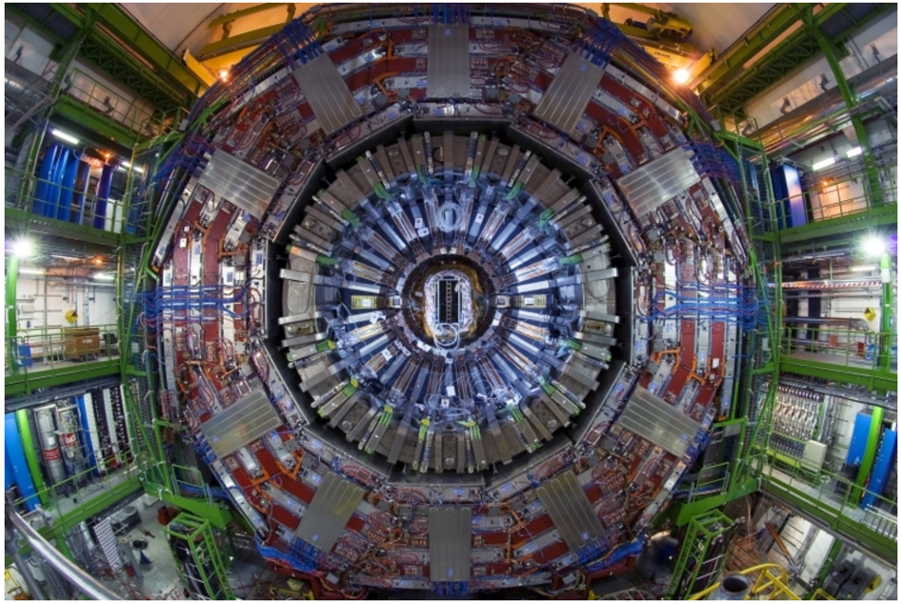

The process began on a Friday evening and, with a visit to two grocery stores to procure the building materials, construction commenced. With a roll of phyllo dough infused with honey and cinnamon acting as the Tracker, some lime gelatine for ECAL, and cookie bars for HCAL (the closest approximation to artillery shell brass that we could find), we came upon the challenge of the solenoid. Chocolate chips were melted down and poured into a beaker with a can of cocoa powder as an inner mandrel, filling the cylindrical gap, and once it solidified, the resulting chocolate cylinder was quite painstakingly extracted. For purposes of structural integrity, additional chocolate was smeared on the outside.

With the challenge of the magnet overcome, we proceeded to construct the muon chambers and the return yoke out of wafer sheets and yellow cake. Our material budget did not allow us to create the correct number of layers of muon chambers and yokes, and the wafers made the outermost layer to provide rigidity. However, in a mix of artistic flair and confused recollection of the true structure of CMS, we chose to paint the muon chambers a bright red. The sheets of wafer were held together with as many toothpicks as there are protons in a beam bunch.

Before we knew it, several hours of Saturday had come and gone, and a recess was called for as mandated by any good health-and-safety manual. We reconvened in the afternoon to bring our work to its glorious conclusion –– and not a moment too soon, as the small party commemorating our creation had already run most of its course by this point. The less glucose-intolerant among us then proceeded to undo our hard work of assembly and munch away at the sub-detectors, and there was much rejoicing!

– By Alexey Finkel, Pamela Vo and Nathaniel Pastika

- Log in to post comments