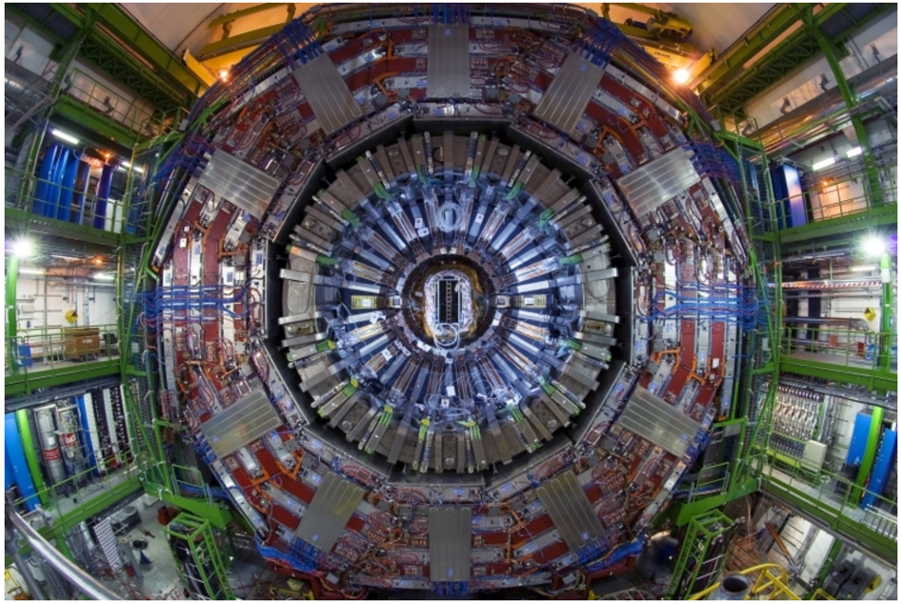

From the CMS experimental site at Cessy, France, located at Point 5 on the LHC ring

The past two weeks have seen several pivotal steps taken towards achieving some of the key goals for CMS during the LHC’s first Long Shutdown (LS1). On 21 October the assembly of YE+4, the new shielding disk located behind YE+3, was completed. The CMS detector was then brought into a configuration allowing for the installation of the muon system’s Cathode Strip Chambers (CSC) ME+4/2 station. Five chambers had already been installed in 2008, leaving the CSC crew with fifteen back-layer chambers, which were installed in just three days, followed by sixteen front-layer chambers, which also took three days. By 8 November, the mechanical activities were complete and the installation of the services (gas, power and optical fibre) to the chambers was kicked off. All services were tested and deemed operational for commissioning by 22 November. During the CSC activities, an opportunity to perform a trial installation of three RE+4 chambers presented itself. On 11 November the Resistive Plate Chambers (RPC) crew rehearsed their installation procedure in-situ. This was useful not only to train the crew but also to further understand and optimise the integration of the sub-detector chambers in CMS. Work on installation of the chambers should start on 4 December. Meanwhile, the re-installation of the refurbished ME+1/1 chambers that started on 30 October has been making steady progress. Initially it was hoped the chambers would be re-installed by 7 January, but work progressed faster than expected and all 36 should now be installed on YE+1 by 30 November. Work continues in parallel to prepare the services and infrastructure for the chamber commissioning. Reconfiguration of the CMS detector to allow for a crucial cold test, where the cooling system of the Tracker will be running at sub-zero temperatures, will start on 7 January. On the –Z end of the CMS underground experimental cavern (underneath the main shaft), the maintenance work on the Drift Tubes (DT) system has nearly been completed, with just the gas leak checks on the RPC remaining. This was the most challenging project foreseen for the DT/RPC team during LS1 as five chambers were to be fully extracted from the central wheel of CMS, YB0, with two to be lowered to the cavern floor. After having carried out the necessary repairs on the chambers located on YB0 and YB–1, the DT crew will now begin dealing with YB–2. On 20 November the –Z endcap (YE–1/2/3) was moved away from the cavern wall in order to access the away-from-interaction-point side of YE–3. Two activities are now taking place concurrently: the installation of a new gas-injection supply system for the YE–3 and RE–4 RPC services by our long-term piping contractor ZEC. The detector will remain in the current configuration until the re-installation of the ME+1/1 chambers is completed, by 30 November. During this time access to the inside of the vacuum tank will remain available thanks to an access gangway and a staircase. This is essential as preparation for the January cold test still requires a lot of work. On the surface, the construction of Building SL53, Point 5’s new visitor reception area, is progressing well. The façade has been erected and the under-floor heating has been installed. The energy-saving features have been fully designed and the procurement of the various electrical and ventilation pieces of hardware launched. As LS1 approaches its mid-point, a tremendous amount of work has already been carried out and many lessons have been learnt. Our collaborators have made every effort to optimise their work whilst maintaining our high safety standards. This is set to continue as we progress towards the challenges awaiting us in 2014. — Submitted by Martin Gastal and Thomas Marriott-Dodington Photos provided by Jesse Heilman, James Cook, Gerd Fetchenhauer and Alberto Benvenuti.

- Log in to post comments