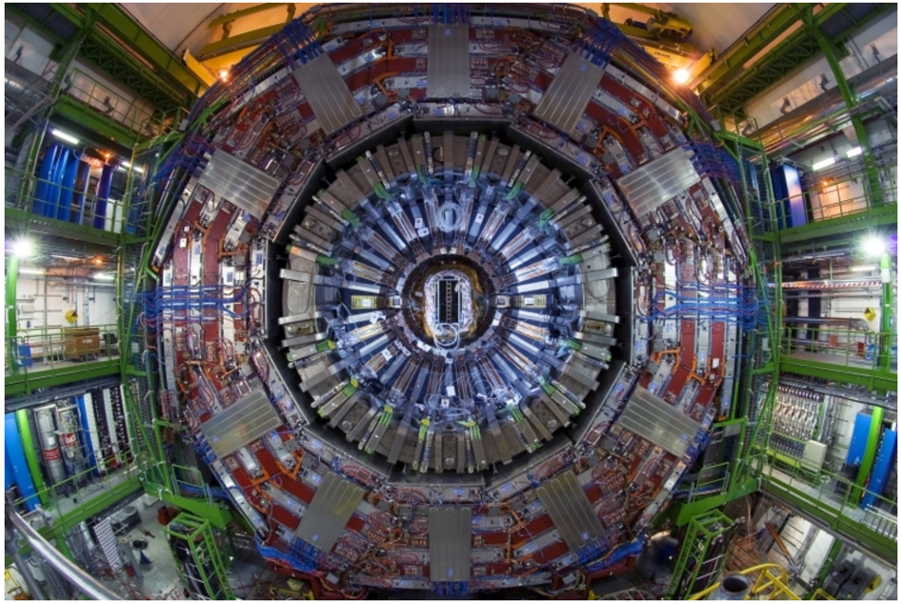

The first wafers of the CMS Read Out Chip (CROC) for the High Luminosity Pixel detector have been produced and tested, marking a major milestone for the next generation CMS Tracker.

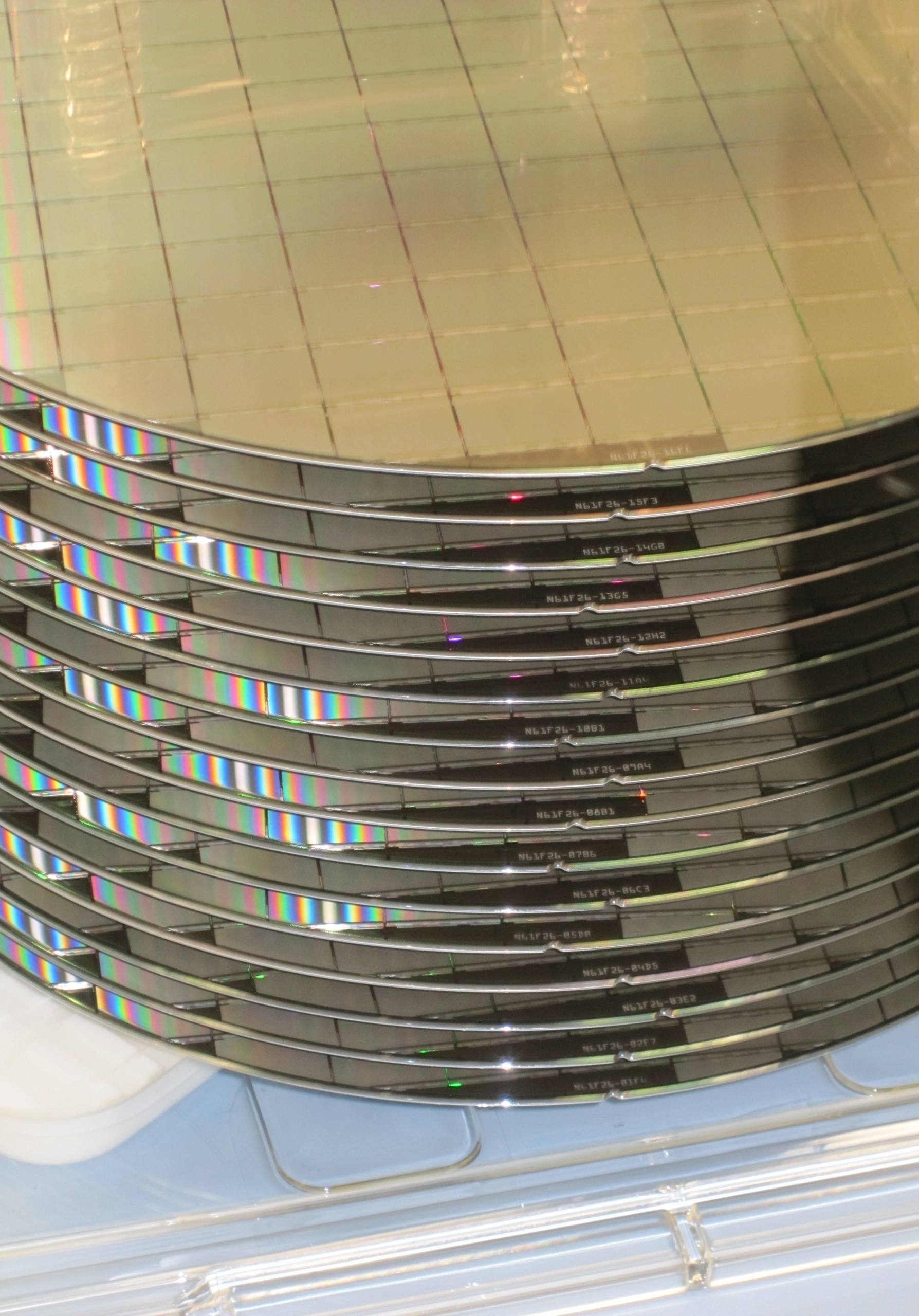

Each silicon wafer contains 136 chips that are built to withstand the most challenging conditions ever encountered at high-energy physics colliders. Twenty wafers of CROCv2 (final CROC version) were produced by TSMC, Taiwan, the largest semiconductor manufacturer in the world. Over 300 more wafers will be produced to build the new CMS pixel detector, called the Inner Tracker.

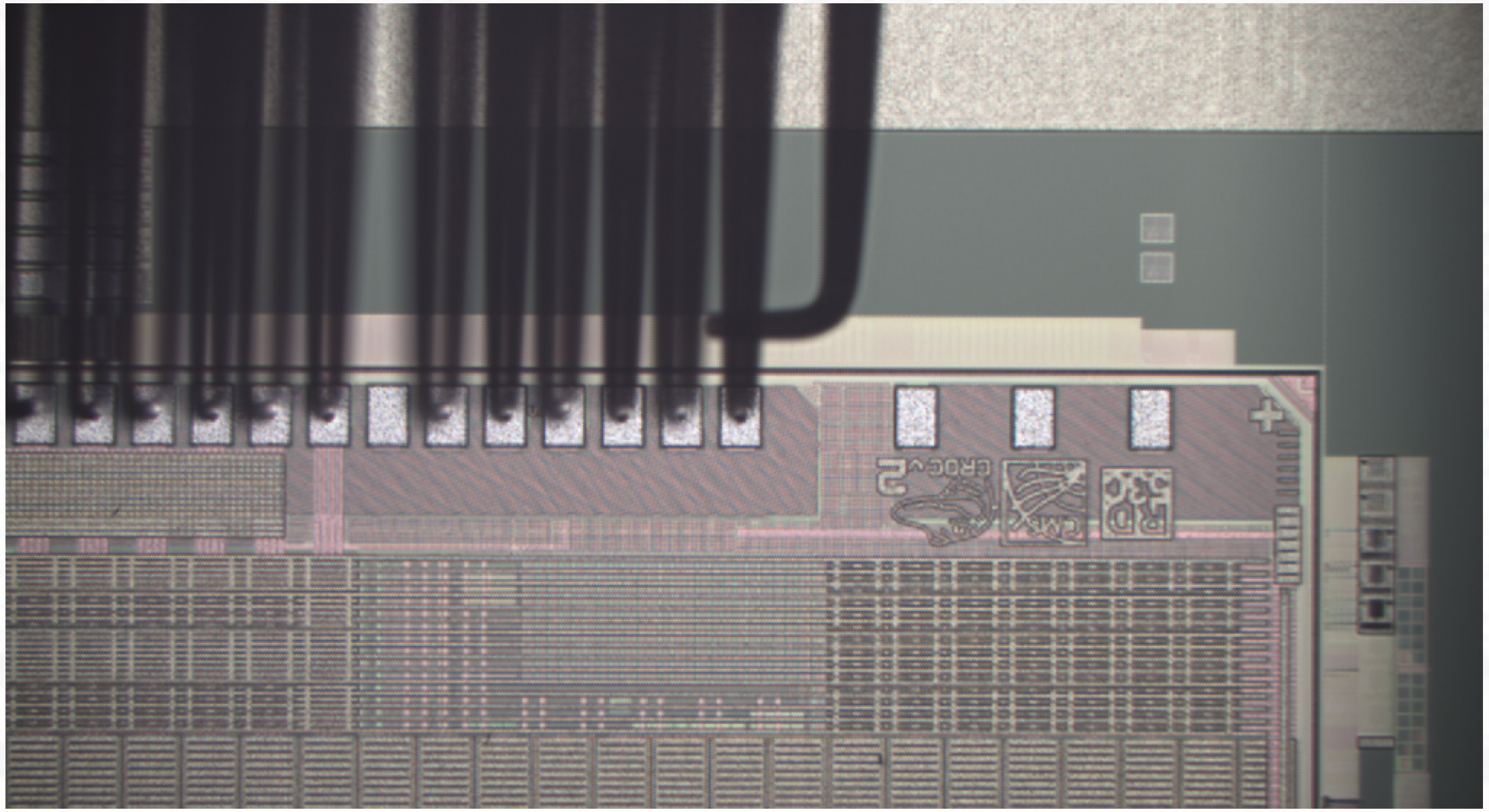

Above: CROCv2 during wafer probing

The Inner Tracker, together with the Outer Tracker, will reconstruct the paths of charged particles as they travel through the detector, which is essential in tracking particles travelling out from the collision point. With its silicon sensors as close as 3 cm to the collision point, the Inner Tracker plays a crucial role in determining exactly where the particles originate (their vertex). Find out more about the tracker here.

Works preparing for the High Luminosity phase of the LHC (HiLumi, or HL-LHC) are well underway for CMS, where many parts of the detector will be upgraded and other parts completely replaced, as is the case for the tracker. It offers an opportunity to push the detector technology further than ever before, and the Inner Tracker is a major part of that evolution.

Higher luminosity creates a much more hostile environment for the detector. This is particularly true for the Inner Tracker as it is so close to the collisions, meaning that the CROC needs to be resistant to radiation roughly equivalent to 100 billion chest x-rays (1 Grad or 10MGy)!

The High Luminosity phase of the LHC will see a maxima of 140 to 200 collisions every time two proton bunches cross, a massive increase from the average 50 collisions CMS currently sees. Therefore, the new chips have to be able to keep pace with the increased number of particles.

The new pixel cells are very small, about the size of a human hair (50 microns by 50 microns), with all the electronics squeezed onto this space. This allows to record and process the passage of 3 billion particles a second for every square centimeter of the detector! Combined with a very high data bandwidth, reaching up to 5 gigabits per second, and a longer memory time, the Inner Tracker will be able to reconstruct a thousand particle tracks each time two bunches of protons meet. The chips are also designed to have very low power consumption, which is incredibly important as the pixel detector will need to be kept at –30°C!

Above: A view of the right corner of the CROCv2 with logos

In order to tackle these challenges, the CROC has been carefully designed by the RD53 Collaboration created in 2013, with 22 institutes from both CMS and ATLAS. Prototype, or ‘demonstrator’ chips were extensively tested through irradiation and beam tests by both the CMS and ATLAS Collaborations. The final chip design (CROCv2) was approved and sent into production in October 2023 after 10 years of design and after passing a multitude of tests and verifications: the chips are deemed ready for installation in CMS for the High Luminosity LHC!

The first CROCv2s wafers have been tested at INFN/University of Torino, Italy and at Kansas State University, United States. Each of the 136 chips present on a wafer is tested individually (about 9 minutes per chip), with a full wafer tested in less than a day. The average yield – or the average fraction of good chips – is high at about 80% after testing more than 1900 CROCv2s. The tests ensure that only the best chips will be used for the Inner Tracker in CMS.

Above: 16 CROCv2 wafers arrive in Torino for testing

With the testing completed, the wafers are now being sent for processing: the square chips will be cut out from the round wafers before being bump-bonded to silicon sensors. The full pixel modules can then be built at CMS assembly centers: over 4000 modules must be produced for the Inner Tracker.

The journey to get the CROC ready was exciting, but there is still a long road ahead to get the Inner Tracker ready for collisions in 2029!

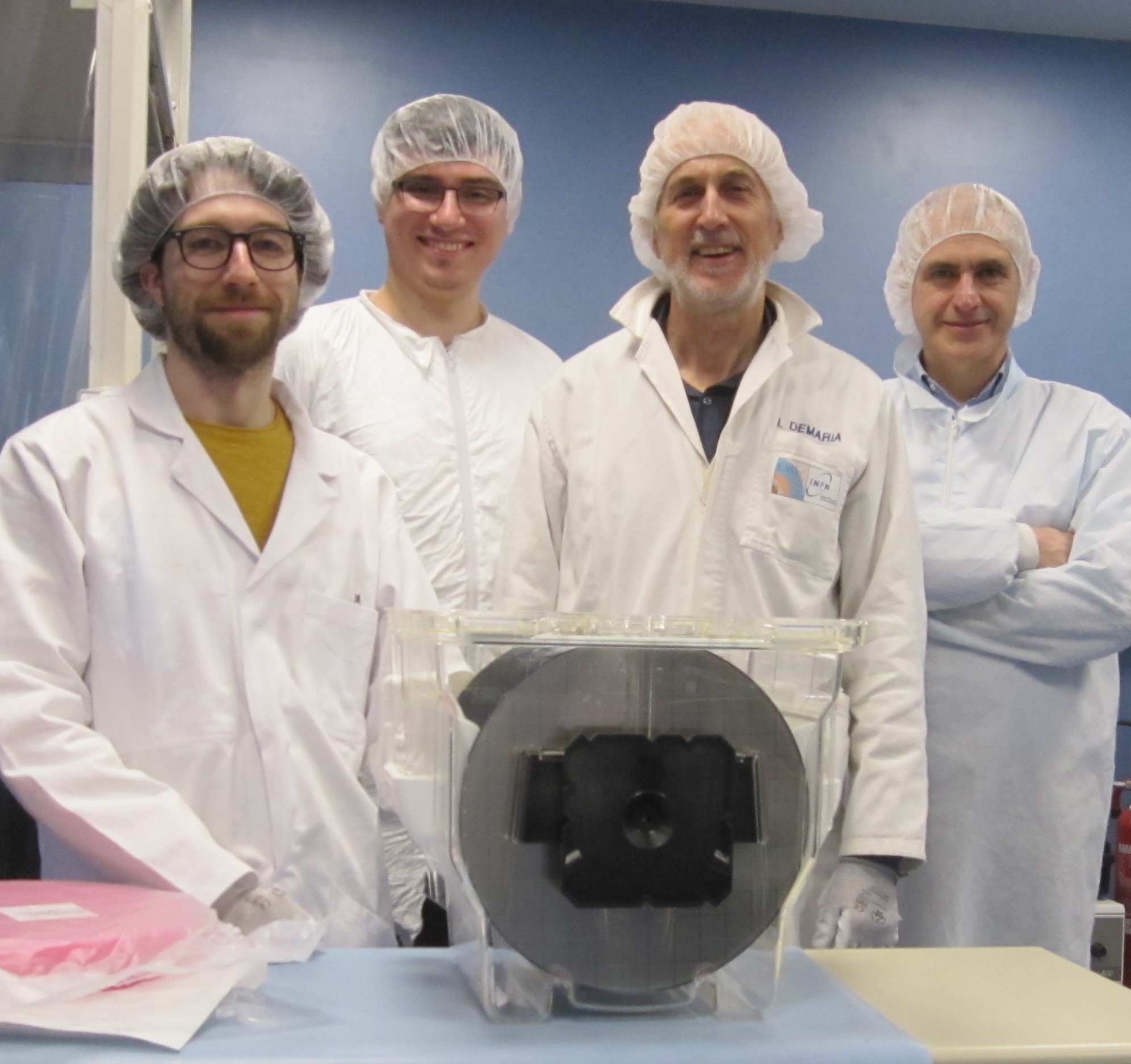

Above: The team during wafer level testing of the CROCv2 engineering run. Fabio Luongo (PhD student, University of Torino), Michael Grippo (PostDoc, INFN), Lino Demaria (INFN researcher), Ernesto Migliore (staff, University of Torino)

Read More