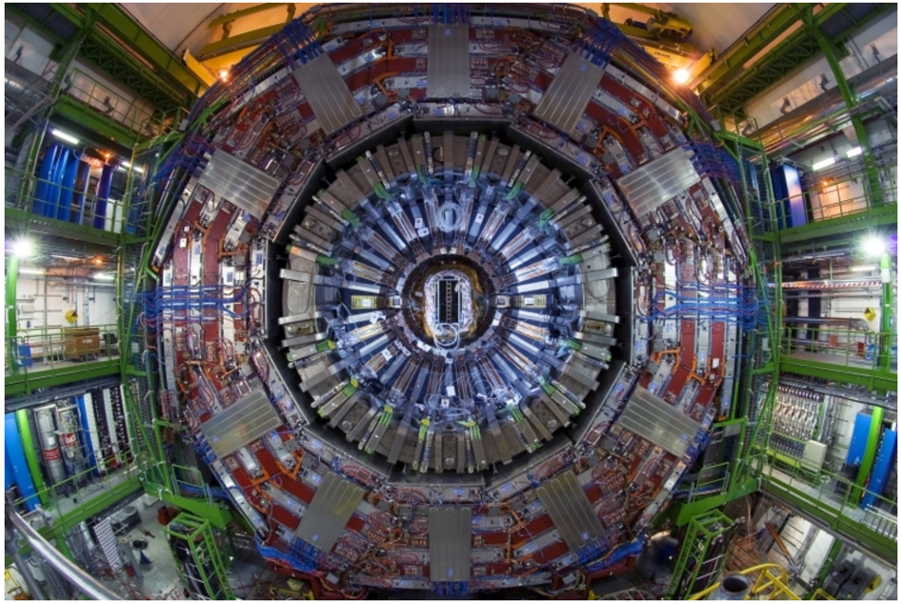

In the same way that loud background noise does not allow us to listen to a conversation or appreciate a piece of music, so too the CMS detector needs a quiet environment to optimize data taking and analysis.

New shielding has been successfully installed around the section of the LHC beam pipe crossing the CMS detector, at one end of the experimental cavern. The beam pipe is the vacuum chamber where the proton beams travels around the LHC and collide in the experiments, including CMS. The new shielding allows a significant reduction in background noise for the CMS detector, meaning that the upcoming data-taking period can begin under improved conditions.

One of the most important sources of background noise for CMS comes from neutrons. During the LHC runs, protons collide in the beampipe surrounded by the CMS detector, and some highly energetic protons scatter from the collision point. They then collide with materials in the vicinity of the beam pipe, creating neutrons. These neutrons hit the muon chambers surrounding the detector and generate unwanted background noise in the data taken by the chambers.

Simulations from the BRIL group (Beam Radiation, Instrumentation and Luminosity) showed that the existing shielding needed to be supplemented in order to tackle the background noise in the muon chambers. This will be especially crucial for the High Luminosity phase of the LHC, where the background noise will increase. The new shielding provides this additional thick, physical barrier separating the muon chambers from the secondary collisions that generate the unwanted neutrons.

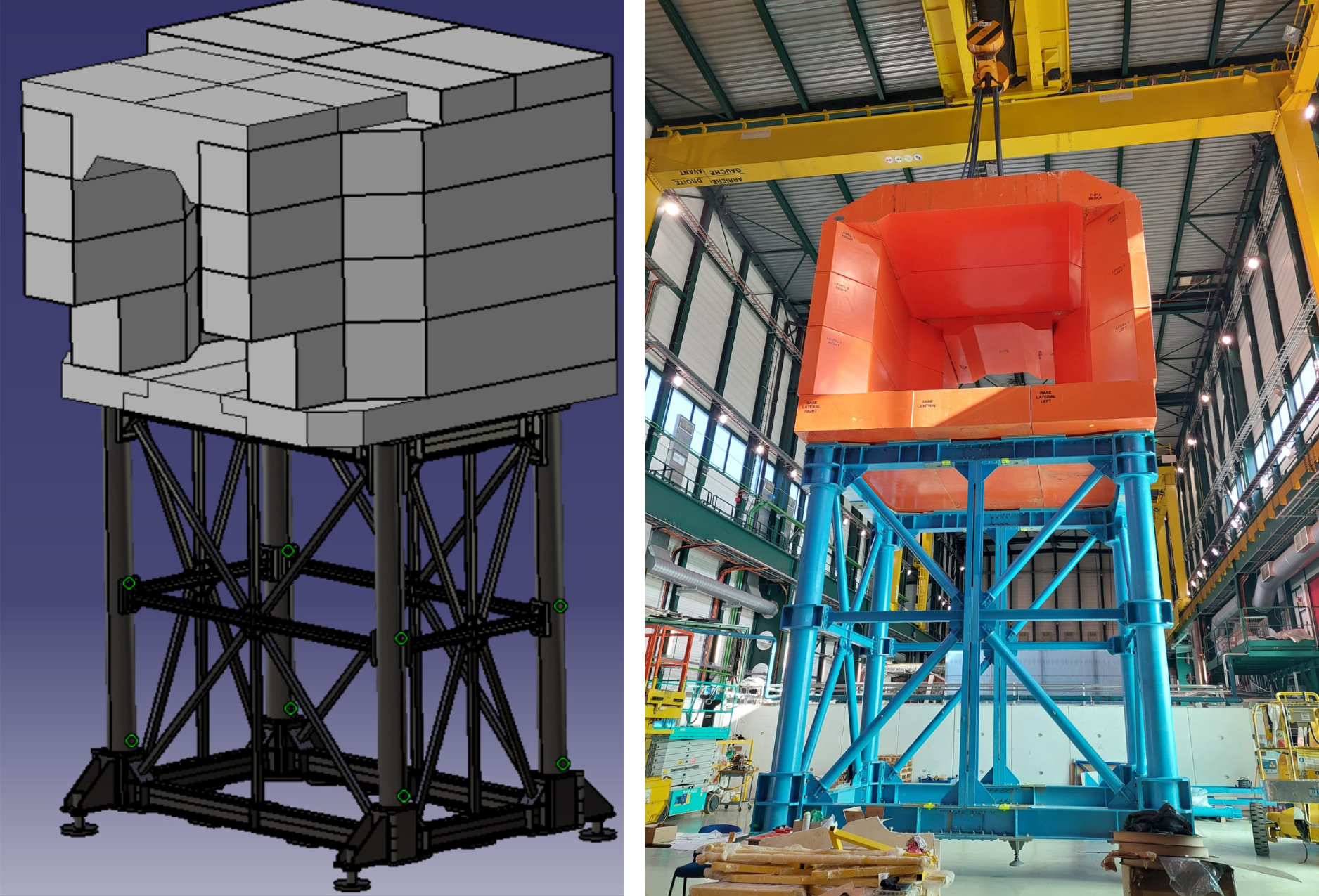

This set of shielding is the first of two to be installed, the second planned for the other end of the detector. Getting the two structures, each measuring 216 cubic metres and weighing 240 tons, inside an already full experimental cavern is a challenging procedure to plan. The limited crane capacity and the narrowness of the passages involved exacerbate the difficulties that the teams have to work around.

In order to accommodate these limitations, the component parts of the shielding were painstakingly lowered 100 metres down the shaft connecting the surface with the underground cavern, and then assembled underground by CERN’s Heavy Engineering Group (EN/HE) and on-site crews.

RIGHT: the Shielding assembled above ground before being pulled apart and lowered underground, with credits to Tristan Loiseau.

The design of the shielding itself and the complex procedure of lowering the blocks into place has been a collaboration between experts from CMS Radiation Simulation, CERN's HSE Radiation Protection, and CMS Engineering & Integration Office. The latter, along with CMS Technical Coordination, also oversaw the installation.

The shielding is made up of smaller blocks, made of a steel container filled with concrete, and supporting towers to keep them in place. The orange blocks and the bright blue supporting tower were produced in Turkey by Arites and DehaTech respectively.